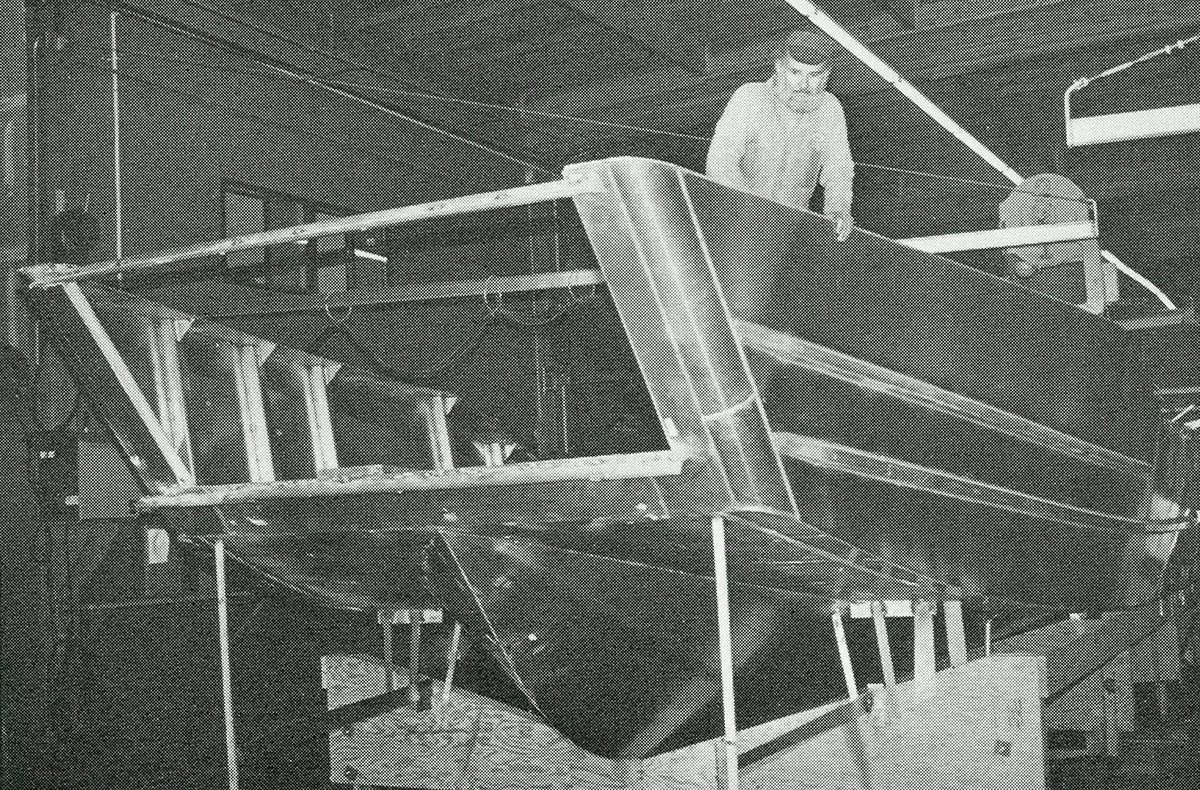

The first Munson Boat

Over sixty years have passed since this photo was taken of the first Munson boat with our founder, Bill Munson, at the tiller. It is sad to say that she was not aluminum and rotted away years ago. Steel rusts, wood rots, fiberglass delaminates and riveted aluminum can’t take a pounding. That’s why Munson Boats are built from all welded aluminum plate.